| Home |

|

|

|

|

Online Store |

|

|

|

If you're visiting our website and the layout looks wrong, try going to your address bar and change the address from "https" to "http". We recently added SSL security to our site, but it is causing some pages to appear without formatting.

Water and Wastewater News - July 2020

Water and Wastewater News - July 2020

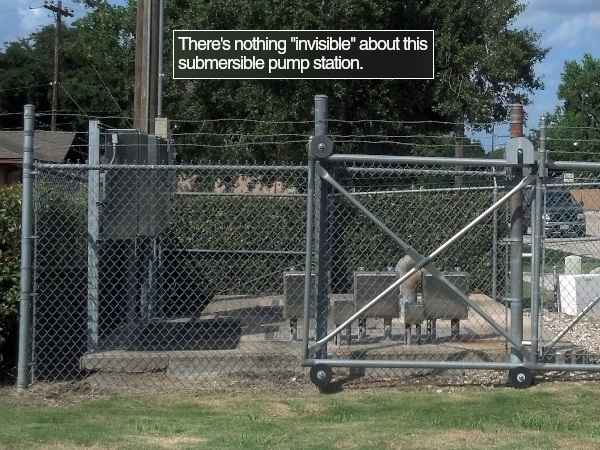

These lift stations are out of sight!

Sometimes the highest priority for a pump station isn't function or reliability -- it's invisibility. When you have valuable real estate and you want it to have an unbroken view, it's understandable that you might want your lift stations to be neither seen nor heard.

Lots of engineers have a gut instinct that a wet-pit submersible pump station with a below-ground valve vault will offer the most invisible option possible. But there's a way to hide a lift station even better than that.

You see, unless you go to some pretty extraordinary lengths, a submersible pump station is still going to have several features that show up above-ground: Power connections, a control panel, a pump hoist (or at least someplace to put it), and in many cases, a fence for safety. And you can't easily hide these things, since you'll almost always need some kind of access for a truck in case the pumps have to be pulled.

And that's not saying anything about provisions for backup power in case of an electrical outage.

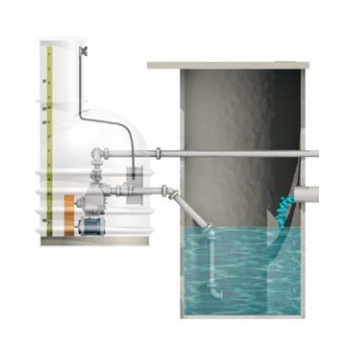

We're here to tell you that not only is there a way to make a lift station even more invisible than a submersible, but also longer-lasting and easier to maintain. The answer is found in the Gorman-Rupp Reliasource below-ground station configuration, using self-priming Super T Series or Ultra V Series pumps.

These stations are available in two diameters: 7.5' and 10'. They come in completely self-contained fiberglass units that can be buried next to the wetwell. The enclosure comes with a water-tight access hatch and entrance tube, providing near-perfect invisibility to anyone passing by. The entrance tube includes an inlet and outlet for the safe and dependable exchange of air by the integral ventilation system (ensuring maximum operator safety). The rest of the station is kept completely out of view -- but also safely separated from the hazards of the wetwell.

Enhancing the safety of the below-ground station is the way it permits operators to conduct any required maintenance or service on the pumps without ever exposing themselves to the wetwell. The pumps use their suction-lift capacity to bring the water up through the suction line before discharging it to the force main. Thus the pumps stay wet on the inside but dry on the outside. And they are driven by ordinary TEFC, ODP, or XP motors powering the pump through a V-belt configuration. That means there's no depending on exotic motor types or cooling jackets, nor is there any need to pull the pumps for routine inspections.

In fact, virtually all maintenance, service, and repair can take place with the pumps and motors remaining safely in place inside the station. A pump could be completely rebuilt in place without ever removing the pipes or lifting the casing. Don't overlook the fact that a self-priming pump can shave 25' off the excavation required for a dry pit -- so even where a deep wet well is unavoidable, one of these pump stations could bring your operators (and all of their tools) 25 feet closer to the surface.

And these pumps last, too. External sight glasses make it easy to check on seal and bearing oil levels with just a glance, and external shimless adjustment means that the pumps can be maintained in peak efficiency without any operator having to encounter the liquid inside. The typical configuration for a Gorman-Rupp municipal self-priming pump will pass a 3" diameter spherical solid, and if the worst-case scenario comes about, the pump can be unclogged through the easy-access coverplate and put back into service in a matter of minutes, at a fraction of the time it takes to unclog a submersible (and none of the cost of calling a service truck).

All told, it's not unusual for these pumps to remain in service for decades at a time with little more than some routine inspections and the occasional oil change. And even when you're pumping the worst, you can rest assured that most of your pump is completely dry and the motor will never be submerged (plus, material upgrades to austempered ductile iron and high-grade stainless steel are available if you really need them).

Best of all, the whole package is factory-assembled and tested before shipment, so you can be confident in a quick installation and a dependable startup.

So if your first priority is to keep your lift station out of sight, the Gorman-Rupp below-ground station option is the best choice for a comprehensive solution that values operator safety, low visibility, and long-term reliability. Contact us for more information or for a look at the options.

Past water and wastewater news updates