| Home |

|

|

|

|

Online Store |

|

|

|

Sign up to receive our free Water Utility Tip of the Day

If you're visiting our website and the layout looks wrong, try going to your address bar and change the address from "https" to "http". We recently added SSL security to our site, but it is causing some pages to appear without formatting.

If you're visiting our website and the layout looks wrong, try going to your address bar and change the address from "https" to "http". We recently added SSL security to our site, but it is causing some pages to appear without formatting.

Many of our pumps are designed for suction-lift applications. For engineered applications, we typically work closely with the designing engineer and the operator to ensure that the pump properly achieves the required hydraulic conditions for good performance. In general, this includes, but is not limited to, detailed calculations of net positive suction head available (NPSHa) from the atmosphere, net positive suction head required by the pump (NPSHr), total dynamic suction lift (TDSL), total dynamic discharge head (TDDH), and total dynamic head (TDH).

For customers of our online store, however, we simply do not have the manpower available to carefully apply all of the required measurements. This is why pumps we sell under these lines are called "non-engineered pumps" or "off-the-shelf" applications. It is the customer's responsibility to evaluate whether the pump is suitable for his or her conditions.

Please Note: These tips apply only to pumps designated as "self-priming" pumps. Pumps come in as many types and sizes as electric motors and computers, so each type needs to be understood on its own.

When evaluating a pump's suitability, consider the following:

last revised 10.14.2005

For customers of our online store, however, we simply do not have the manpower available to carefully apply all of the required measurements. This is why pumps we sell under these lines are called "non-engineered pumps" or "off-the-shelf" applications. It is the customer's responsibility to evaluate whether the pump is suitable for his or her conditions.

Please Note: These tips apply only to pumps designated as "self-priming" pumps. Pumps come in as many types and sizes as electric motors and computers, so each type needs to be understood on its own.

When evaluating a pump's suitability, consider the following:

- Elevation at the site. Atmospheric pressure available at sea level is much greater than at elevations in the Rocky Mountain region. Standard air pressure in Miami (near sea level) is nearly six feet greater than in Denver (at one mile above sea level). The curves shown for each pump show performance at sea level; thus, if you are in Denver, you should subtract about six feet of "head" (pressure) from the pump performance shown. This means that a pump with a maximum suction lift of 18' at sea level may only be able to achieve a suction lift of about 12' in Denver. As a rule of thumb, subtract about 1.2' of performance for every 1000' in elevation above sea level.

- Horizontal runs of suction hose. It is more difficult for a pump to evacuate a long run of suction hose than vertical hose. While this may seem counterintuitive, consider the following:

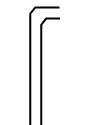

The Best Installations Have No More Than a Very Short Horizontal Run

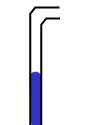

Empty hose The pump draws a vacuum, allowing atmospheric pressure to push the water column into the hose As the pump creates a stronger vacuum, the water column rises higher in the hose Once the pump has reached "prime", the hose is full and the pump enters dynamic operation Long Horizontal Runs Are Hard on the Pump

Empty hose When the pump is faced with a long horizontal run, the pump has to evacuate a much larger volume of air before the water column reaches the pump For a 2" diameter hose, the volume of air to be evacuated from each foot of hose is about 38 cubic inches. In the vertical position, every time the pump evacuates 38 cubic inches of air, the water column rises by one foot. But supposing a 10-foot horizontal run of hose that lies basically flat, the pump has to evacuate 38 cubic inches times 10, or 380 cubic inches, just for the water column to rise the last few inches. In other words, it may take more work for the pump to move the water through the last three inches than through the first ten feet. This can cause the pump to take a very long time to prime or prevent it from priming altogether, even if the total suction lift is less than what the pump is normally capable of doing. Sometimes Performance Can Be Improved By Making the Suction Column Taller

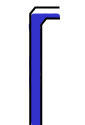

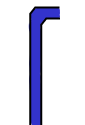

Empty hose Though it may also seem counterintuitive, the problem of a long horizontal run can often be solved by adding suction distance By raising the pump up just a couple of feet, the operator can change the long horizontal run into a sloped run. Though it's still harder for the pump than a true vertical suction lift, it is much easier than a horizontal run. Of course, you should still not exceed the rated suction capacity of the pump. Naturally, every set of conditions is unique. It's always best to be conservative when estimating what the pump can do and what it will be required to do.

last revised 10.14.2005